by Bill Ball

The oil and gas industry has a reputation for being slow to adopt new technologies. The phrase “Because we’ve always done it that way” often stifles innovation. However, the limitations of traditional gunbarrel tanks in today’s oilfields are forcing a reevaluation of this long-held approach.

The Rise and Fall of Gunbarrel Tanks

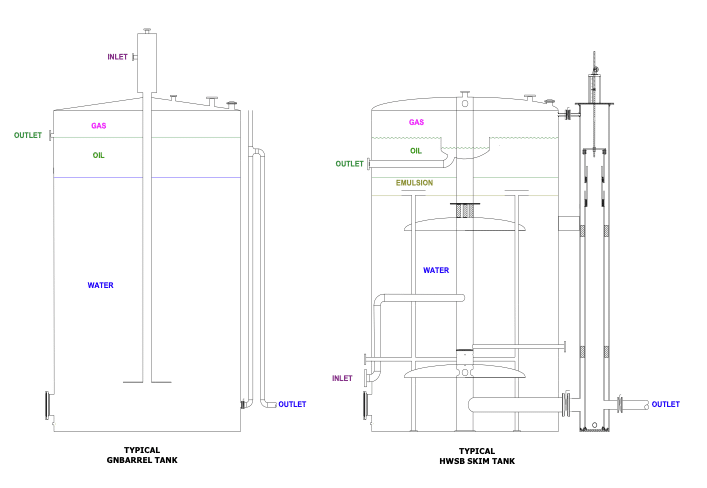

Gunbarrel tanks, named for their resemblance to a gun barrel when viewed from above, have been used since the 1870s to separate oil and water. Their simple design, with a central downcomer pipe and gravity-based separation, worked well when oil production had low water content.

However, the advent of waterflooding, a technique to enhance oil recovery, dramatically increased the amount of water produced alongside oil. Gunbarrel tanks struggle to handle these high water cut conditions, leading to inefficient separation and significant oil carryover into disposal wells.

The High Cost of Inefficiency

Oil carryover isn’t just an environmental concern; it’s a financial one. Lost oil translates to lost revenue. Additionally, the oil-contaminated water can cause plugging in disposal wells, necessitating costly maintenance and workovers.

A 21st-Century Solution: The HWSB®

In 1989, a patented design emerged to address the shortcomings of gunbarrel tanks in high water cut scenarios. The HWSB® (hydro-dynamic water separation breakthrough) boasts a radically different design that prioritizes water retention time, ensuring maximum oil recovery.

With an innovative system of baffles and flow paths, the HWSB® achieves significantly longer retention times than gunbarrel tanks, resulting in near-perfect oil-water separation. The benefits are clear: increased oil recovery, reduced maintenance costs, and improved environmental performance.

The Economics of Change

While the initial cost of an HWSB® is higher than a gunbarrel tank, the long-term financial benefits far outweigh the upfront investment. Eliminating oil carryover and reducing well maintenance expenses can lead to substantial cost savings and increased profitability.

Conclusion

Gunbarrel tanks served the oil industry well for generations, but their limitations in modern high water cut production are undeniable. The HWSB® offers a compelling alternative, delivering superior separation efficiency and economic advantages. As the industry embraces innovation, it’s time to consider whether gunbarrel tanks have truly become obsolete. Sources and related content

Read the technical paper, GUNBARREL TANKS: Could Yours Be Obsolete?

Bill Ball is a senior staff consultant to KBK Industries with over 50 years of oilfield engineering experience and holder of twenty-three oil and gas industry related US patents. His credentials represent the culmination of a lifetime of breakthroughs and innovations. Bill’s twenty-three US process equipment patents speak to this. His first patent has become an industry “game changer.” It is the industry’s first true oil-water separation “skim tank”, the “HWSB”. Today there are over 3,500 HWSB® skim tanks separating and capturing oil that used to be injected and lost forever. Bill resides in Bixby, a suburb of Tulsa, Oklahoma.