- 785-372-4331

- info@kbkindustries.com

- 25025 Interstate 45, Suite 520, The Woodlands, TX 77380

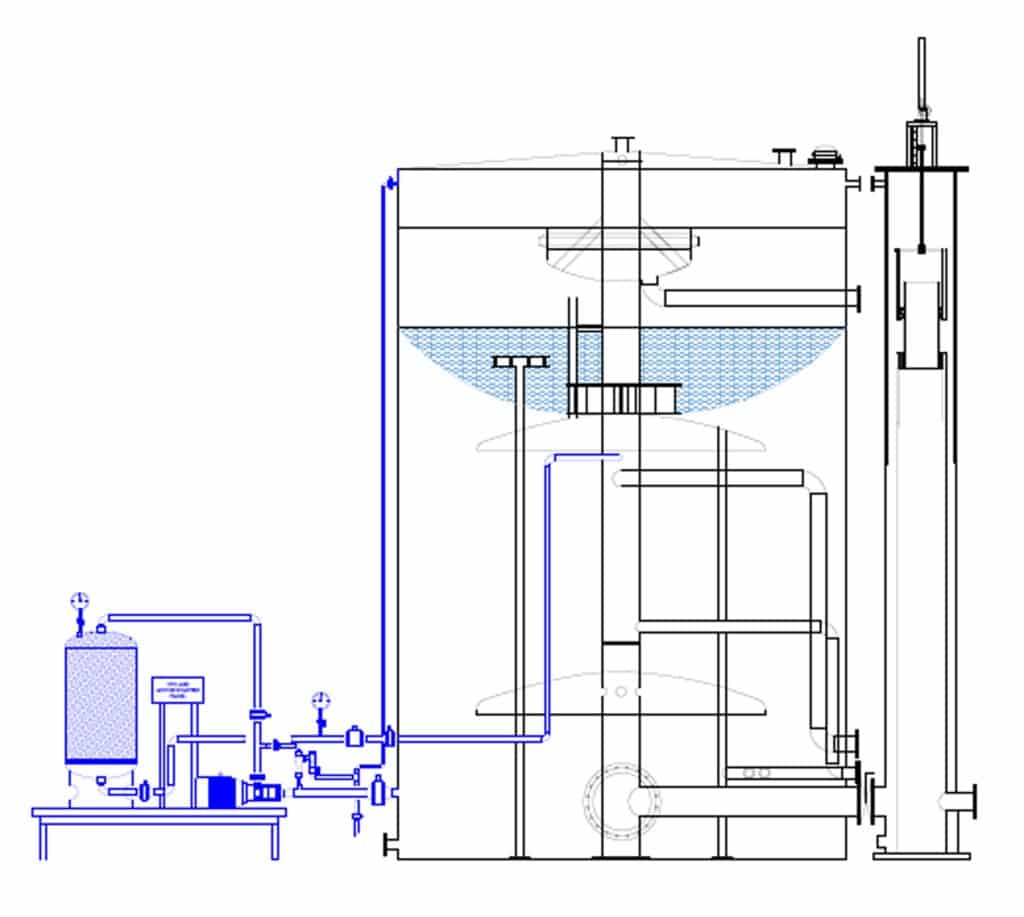

KBK HWSB® Oil Recovery tanks are the centerpiece technology of our oil-water separation system. Featuring a patented design that is becoming the industry standard for SWD plants, water floods and production separation applications. The HWSB® captures 5x more oil versus traditional gunbarrel tanks.

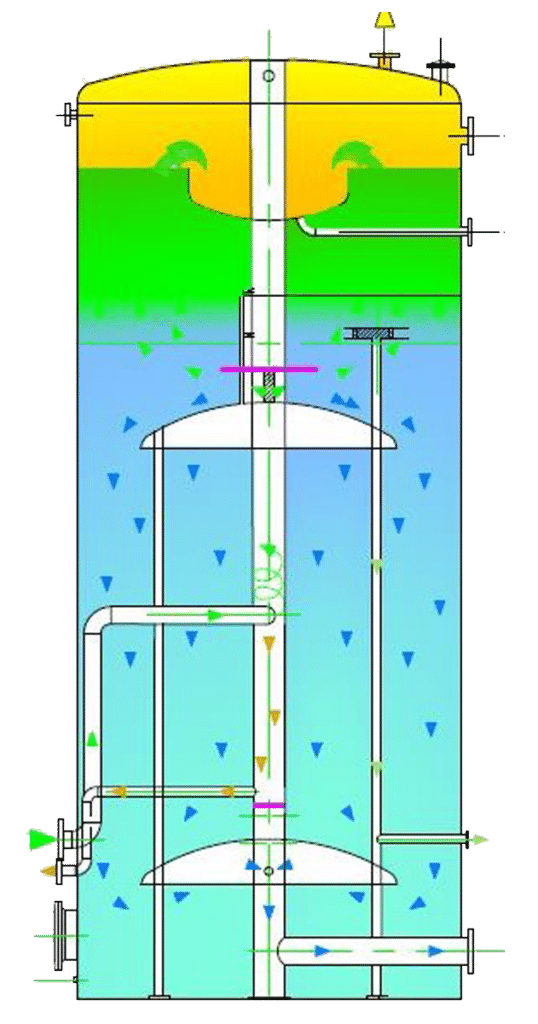

Further enhancing the HWSB® is the addition of a dissolved air flotation system. The process works as follows:

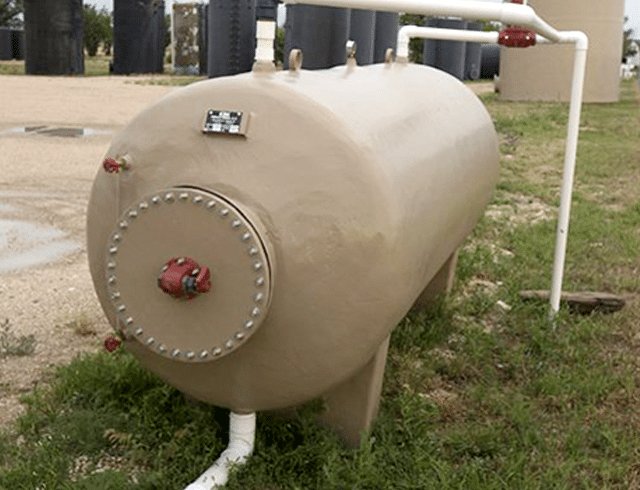

Gunbarrels are available in capacities ranging from 100 to 1,500 barrels. Standard gunbarrels come with center flume and spreader table, and are complemented by high-quality fittings and flanges, couplings, manways, thief hatches and gaskets. Gel coats and pigments are available in a variety of colors, to protect the exterior of the tank from ultraviolet (UV) rays.

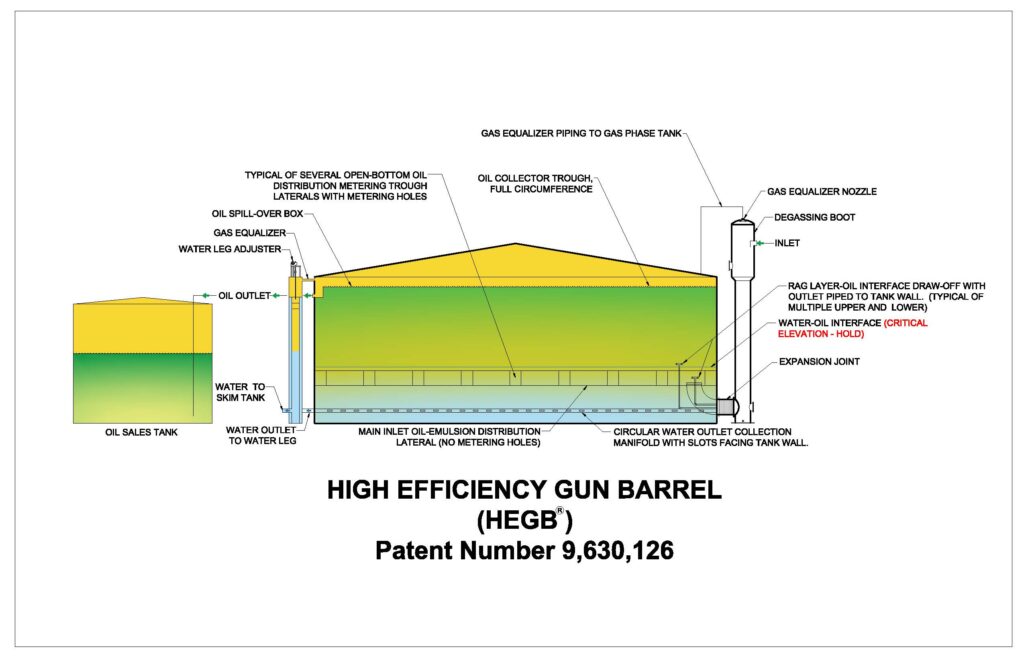

KBK’S HIGH EFFICIENCY GUNBARREL, OR HEGB, is 21st century adaptation of the 100+ year old industry standard “Gunbarrel Tank”.

One hundred years ago industry founders and operators had little knowledge of hydraulics or the value of uniform fluid distribution. Today, however, most of us understand that a major key in processing is retention time, and that the best way to achieve it is through uniform distribution of fluids.

The design of the HEGB focuses entirely on the uniform distribution and collection of fluids. The result is very high hydraulic efficiency; thus, the name High Efficiency Gunbarrel, or HEGB.

The HEGB® uses a series of open bottom troughs sized to slow the flow rate of the fluid. The HEGB® is more than four times more efficient than an equivalently sized gunbarrel.

Gel coats and pigments are available in a variety of colors, to protect the exterior of the tank from ultraviolet (UV) rays.

KBK’s free water knockouts have been heavily adopted in areas of lower pressure wells with corrosive produced fluids. These fiberglass FWKO’s offer a significantly longer life than a steel alternative in this application.

The goal of the design of this water collection/storage tank is to 1) maximize retention time by redirecting the inlet flow to minimize that flow through the normal path of least resistance, and 2) to provide for the automatic skimming of oil from the top of the water collected/stored water layer below.

The result is for an oil layer to accumulate on top of the water, regardless of the tank’s fluid level. As more water flows through the tank more oil accumulates, building an ever-thicker (deeper) layer of oil above the water. Since the throughput rate of the inlet water stream in most process plants is rarely 100% consistent, the overall level in tanks used for this purpose is ever changing.

Automating the skimming function is the key to maximizing oil recovery and preventing tank overflows and resulting oil losses. Automating this skimming function also takes the human element out of the skimming process, freeing up operation personnel to perform other tasks which may require less precision.

The automation system necessary to accomplish automatic skimming employs a transmitter, a valve, and a pump. When setup per KBK’s patented design, this system will pump the oil directly into the oil storage tanks.

This allows all freely separable water to separate from the oil according to Stokes’ Law when it reaches the oil storage tanks, rendering the oil emulsion free.

Founded in 1975, KBK Industries is a tank manufacturing firm that helps businesses solve their storage and separation needs. KBK’s patented tank technology offers engineered solutions to businesses dealing with oily water, suspended solids or entrained gas. Our industry certifications give assurance that KBK is committed to Quality.