- 785-372-4331

- info@kbkindustries.com

- 25025 Interstate 45, Suite 520, The Woodlands, TX 77380

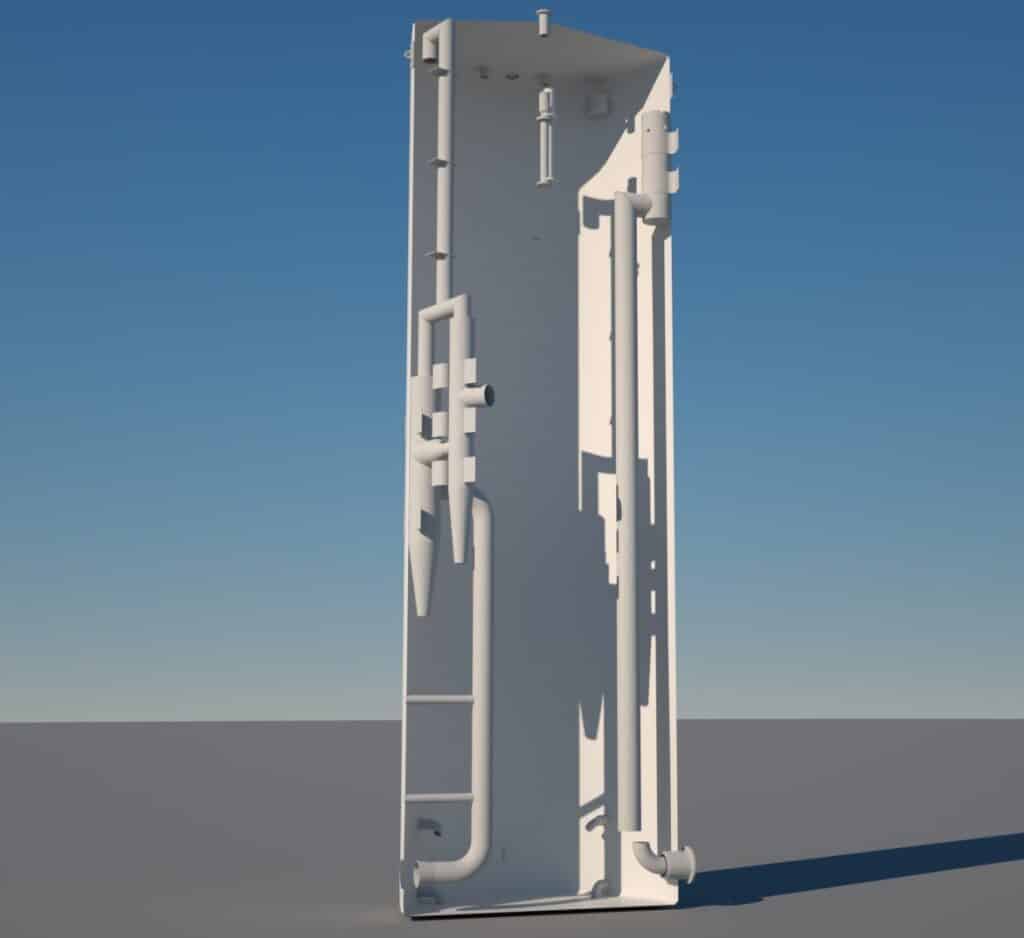

Rely on our patented DFSD® Desander technologies to efficiently remove the abrasive solids from fluid streams. The DFSD® desander will prevent solids from filling tanks in your battery and will protect downstream piping and pumps from solids damage.

Captures Smaller Sized Particles

Captures solids to consolidate them in one vessel before they can redistribute into downstream facilities.

Increased Gas Handing

De-gases inlet fluids to eliminate gas-related mixing energy in downstream separation systems.

Easier Solids Removal

Easily remove captured sand without physical entry into the tank

Hydraulic Flow Splitting

Uniformly divides the outlet flow into two or more equal streams via its hydraulic flow splitting design

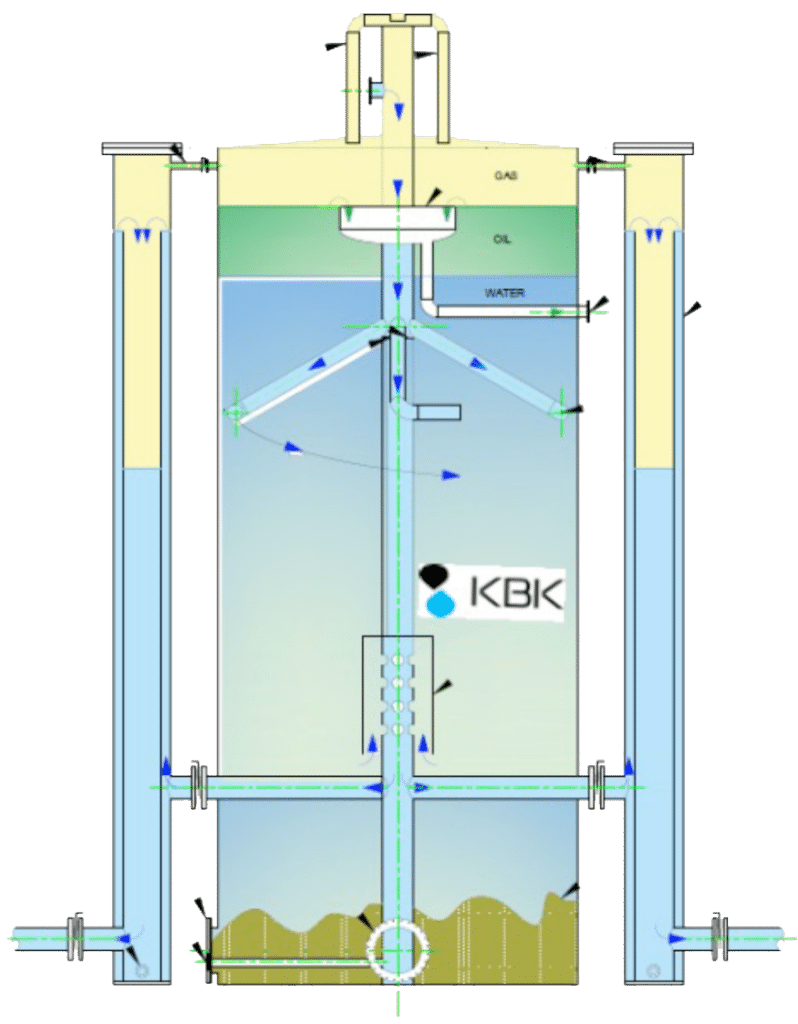

The OSDST® captures solids from fluids found in pipelines. This specialized oil recovery and desanding tank designed for 30,000 BPD and rated for slug flows of 220,000 BPD and 20,000 BOPD.

The OSDST® is utilized in pipelines and before central tank batteries to prevent solids loading.

This tank captures the suspended solids before these solids damage piping, valves, meters or accumulate and block the system.

The OSDST® is patented and owned exclusively by KBK Industries, LLC.

Founded in 1975, KBK Industries is a tank manufacturing firm that helps businesses solve their storage and separation needs. KBK’s patented tank technology offers engineered solutions to businesses dealing with oily water, suspended solids or entrained gas. Our industry certifications give assurance that KBK is committed to Quality.